| Speed: | Adjustable By Speed Controler | PCB Type: | FR4 CEM1 CEM3 Aluminium |

|---|---|---|---|

| Price: | Negotiation | Application: | All Type PCB |

| Driven Type: | Motorized | Warranty: | One Year |

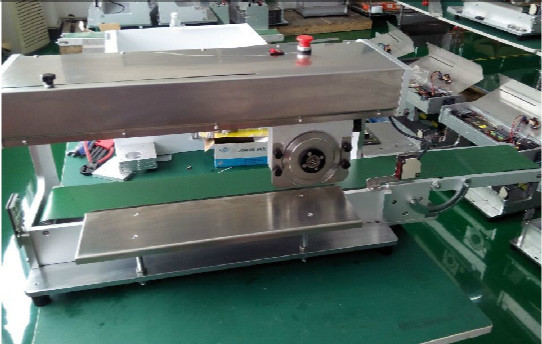

Automatic FR4 CEM1 PCB Depaneling Equipment Motor Driven With Speed Controller

1. This PCB cutting machine ,we adopted imported SHD61 high speed steel for cutter,circular cutter ID 125mm, the under straight cutter ID 360mm, working temperature:10-35℃, storage temperature -20-50℃.

2. it can cut the following PCB:

A, the PCB board thickness : 0.2-5mm

B, V shape MIN size: 0.25mm

C, the PCB board V shape thickness: 0.25-2.0mm

D, Between the component and PCB board distance is 1.0mm

E, The component the biggest high :35mm

F, The under cutter that can adjust : 0-50mm

H, we use the computer program control, excat and standy, it can cut 0-360mm one times.

V-CUT PCB Separator machine features:

1. Firm machine structure be designed to prevent electronic circuit, solder point, and solder singulating area of PCB from damage by unsuitable force.

2. Effectively reduce stress and prevent solder point chap from PCB singulating .

3. PCB singulating speed can be adjusted by the rotary knob.

4. PCB singulating stroke can be set free and setting value can be showed in LCD.

5. Clearance between circular and linear blades are adjusted to fit different V groove depth and compensates for blade wear out.

6. Optional PCB conveyor belt to remove finished PCB singulation .

Automatic PCB Separator machine Competitive Advantage:

To avoid welding spot cracking and deceasing physical strength during cutting process.

PCB aim at V-CUT when sub-boarding, to get into cutting process under function of plunging cut and wheeling.

Guide plate in and out can ensure personal safety when cutting, woke piece has great reliability.

Special platform devices, any length of the PCB boards are available, especially for the LED. For LED Aluminum PCB, two heads conbine into one set , which can cut it well.

FAQ About PCB V CUT Machine YES-1:

1. Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.

2. Q:What is warranty of the machine?

A:1 year.

3. Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe transportation.

4. Q:What is life time of machine blades?

A:About 6-12 months.

5. Q:What is material of blades?

A:Japan high speed steel SKH-9

6. Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.

7. Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client if needs.

8. Q:Can we see your machine in our country?

A:Yes, we would like to offer contact details of our clients who are using our machines.

Our PCB Depanelizer Service

|

1. Engineers available to service machinery oversea |

|

2. Mature technique & forerunner to process makes high quality machinery |

|

3.Effective customer service |

|

4.One year warranty for the machines except accessories |

ASCEN technology co.,ltd specializing in the SMT automatic equipment and provide the automatic solution for the smart factory for save more producing cost.

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*